Automated liquid packaging has emerged as a critical component in enhancing efficiency and accuracy in modern production lines. This process involves the use of advanced technology to automate the filling and packaging of liquids in an array of production processing businesses in the food, beverage, cannabis, pharmaceutical, chemical, and cosmetic industries. For instance, the food and beverage industry benefits immensely from automation by ensuring precise measurement and hygiene standards, elevating the quality and safety of products.

Similarly, the cannabis industry relies heavily on automated liquid packaging for accurate dosages and secure packaging, instrumental in sustaining consumer trust. In the pharmaceutical sector, precision and consistency are paramount; automating liquid packaging addresses these needs, ensuring that each product adheres to stringent industry standards and regulations. These are just some examples of how automation transforms liquid packaging operations.

This blog post will highlight how this helps improve manufacturing speed and accuracy.

1. Increased Production Speeds through Continuous Operations

Automating liquid packaging processes greatly enhances production speeds by enabling continuous operations, significantly reducing the downtime usually seen with manual processes. Automated systems can function round the clock, maintaining a constant production speed, which is particularly beneficial in meeting high demand promptly and efficiently. The systems are designed to facilitate faster production turnarounds. By harmonizing the speed of all packaging processes, you achieve a more streamlined and faster production line, enhancing overall productivity and meeting market demands in a timely manner.

Beyond just speed, automation brings in the element of reliability in production. Businesses can anticipate a steady output without the unpredictability brought about by human labor — such as unexpected sick days or variations in individual worker pace. This results in a significant improvement in meeting delivery timelines, establishing a trustworthy reputation for the business. With continuous operations, there is also a reduced need for rushed processes, which often compromise the quality of the final product. This balance of speed and quality ensures a steady, reliable supply of superior products to the market.

2. Enhanced Precision and Consistency

Automation ensures a high degree of precision and consistency in liquid packaging. By utilizing sophisticated algorithms and sensors, these automated systems are capable of dispensing exact quantities of liquids into the packaging, maintaining a uniformity that is hard to achieve through manual efforts. This reduces wastage arising from overfilling or underfilling and ensures that products meet regulatory standards consistently. It also guarantees customer satisfaction as each product maintains a consistent quantity, establishing trust in the brand.

Additionally, precision in automation extends to the accurate labeling of products, a crucial factor in industries where a minor error can result in serious consequences, including legal repercussions. Automated labeling processes ensure each package contains the correct information, enhancing brand loyalty while avoiding costly recalls. This meticulous approach to packaging engenders a reputation for reliability and quality, as products maintain a standard of consistency that is trusted by consumers and meets the stringent demands of regulatory bodies.

3. Integration with Advanced Quality Control Systems

Automated packaging lines also benefit from integration with advanced quality control systems. These systems provide real-time monitoring and feedback, enabling a swift response to any deviations in product quality. It ensures that only products that meet the specified standards reach the consumers, safeguarding the brand's reputation and maintaining a high level of customer satisfaction. The data collected during the packaging process also offers insights into the production process, assisting in making informed decisions and optimizing operations over time.

Real-time quality control goes a step further in establishing a brand's reliability and commitment to quality. Automated systems can immediately identify and reject products that deviate from the set standards, ensuring a consistent quality in the products that reach the market. The integration allows for seamless product tracking and tracing, offering stakeholders a transparent view of the production process and enhancing compliance with regulatory requirements. It creates a system where quality is assured and verifiable.

4. Reduction in Human Error

Automation significantly reduces the potential for human error, a common occurrence due to fatigue or oversight in manual operations. Automated systems follow programmed protocols meticulously, guaranteeing uniform output at all times. This not only prevents errors in the quantity of liquid packaged but also avoids mislabeling, ensuring that the right products reach the right consumers, therefore mitigating risks such as product recalls or damages to the brand reputation arising from inconsistent product quality.

The reduction of human error also means safer products for consumers. Issues such as contamination can be significantly reduced, ensuring that products maintain a high standard of hygiene. Automation also facilitates a rapid response to any issues identified, with systems often able to automatically rectify errors, reducing the downtime associated with stopping production lines to address issues manually. In a broader perspective, it creates an environment where quality and safety are paramount, providing products that consumers can count on.

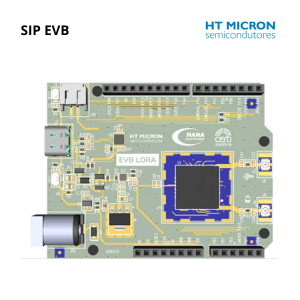

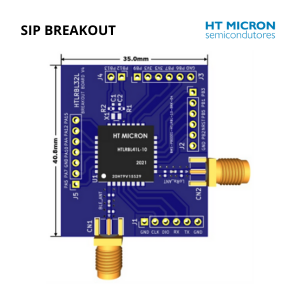

5. What Is an IoT Device and What Is Its Impact on Manufacturing?

An IoT device is a physical device that connects to the Internet. These devices are all around you, and include pool heaters, fitness trackers, thermostats, appliances, locks, smart homes, and more! The Internet of Things is already very present in our lives and will introduce incredible opportunities over the next five years. For manufacturing, IoT devices can provide efficiency and real-time updates and insights. However, it’s essential to have customer confidence, and to do so, companies must ensure that their security and privacy protections are up-to-date and robust. Unfortunately, not all companies do so in a rush to get products on the market.

Without security norms and responsible practices, we’re reaching a crossroads where regulation may be required. Yet, in reality, legislation by itself will not be effective. Passing a law will take too long and will never keep pace with the evolving threat landscape. Companies will individually need to be proactive and increase the level of security for their IoT devices and related services to protect consumers and the privacy of their data going forward.

6. Scalability to Meet Production Demands

Automated liquid packaging systems have the distinct advantage of scalability, adapting easily to meet changing production demands. These systems can be scaled up to accommodate business growth or scaled down in low-demand periods without compromising the speed or accuracy of the packaging process. This ensures that manufacturers can respond swiftly to market demands, fostering business agility and maintaining a competitive edge in the market.

Scalability also allows for experimentation and innovation. Businesses can easily adapt their production lines to introduce new products to the market, testing them on a smaller scale before ramping up production if they are well-received. This flexibility encourages innovation, allowing businesses to rapidly respond to changing consumer preferences and trends. It also facilitates efficient resource management, as businesses can allocate resources more effectively based on the scaled production needs, optimizing costs and enhancing profitability.

7. Optimized Labor Allocation

Automation of repetitive and labor-intensive tasks in liquid packaging processes means employees can focus on more strategic, value-added activities. This not only leads to a more skilled and engaged workforce but also facilitates improved production strategies and fosters innovation. In addition, automating dangerous tasks can create a safer work environment, reducing the potential for accidents and enhancing worker well-being.

By freeing up human resources from repetitive tasks, businesses can nurture creativity and strategic thinking, fostering a culture of continuous improvement and innovation. It encourages employees to upskill, adding more value to the organization and building a team that can strategize for growth and efficiency. Optimized labor allocation also means a happier workforce, as employees find their roles more fulfilling, which can lead to increased job satisfaction and retention, creating a more harmonious and productive work environment.

8. Compliance with Regulatory Standards and Norms

In industries such as food, beverage, cannabis, pharmaceutical, chemical, and cosmetic, adherence to stringent regulatory standards is paramount. Automating liquid packaging facilitates easy compliance with such norms through precise control over the packaging process, ensuring that products meet the requisite safety and quality benchmarks.

For instance, in the pharmaceutical and food sectors, there is a necessity for exact measurements and stringent quality controls to ensure consumer safety. Automation enables integrating systems that can automatically maintain these exact measurements and control standards, reducing the risk of non-compliance. Automated systems can also be equipped to generate automatic reports and documentation required for regulatory compliance, thereby ensuring transparency and adherence to the required norms.

Conclusion

While automating liquid packaging addresses the pivotal needs of a variety of industries, it's important to understand that different industries have distinct requirements. There's no one-size-fits-all approach. A customized liquid packaging solution caters to specific industry needs, offering flexibility and optimizing the production process to meet unique demands effectively. Customization accommodates diverse requirements, offering a tailored approach that ensures optimal performance.