Platforms (277)

The convergence of various technologies is no longer a luxury but a necessity for business success. If you run an eCommerce store, you're already aware of the importance of Search Engine Optimization (SEO) for visibility, traffic, and ultimately, conversions. But have you ever considered how the Internet of Things (IoT) can further enrich your SEO strategy? As disparate as they may seem, IoT and SEO can intersect in fascinating ways to offer significant advantages for your eCommerce business. Let’s delve into the symbiosis between IoT data and eCommerce SEO.

Why Should eCommerce Care About IoT?

IoT can do wonders for the eCommerce sector by enhancing user experience, streamlining operations, and providing unparalleled data insights. Smart homes, wearables, and voice search devices like Amazon's Alexa or Google Home are becoming standard accessories in households, which means that consumers are using IoT for their online shopping needs more than ever.

Integrating IoT Insights into UX Design

IoT data isn't just for SEO; it can also transform your site's User Experience (UX) design. By analyzing real-time user interactions captured by IoT devices, you can refine your site layout and navigation for optimal user engagement and conversion. This seamless blend of IoT insights and UX design elevates your eCommerce platform, making it more responsive to user needs and behaviours.

Unlocking User Behavior Insights

One of the most direct ways IoT can impact your SEO strategy is through enhanced data analytics. Devices like smartwatches or fitness trackers could provide valuable information on consumer habits, routines, and preferences. By integrating this IoT data into your SEO strategy, you can better understand your target audience, refine your keyword focus, and tailor your content to better suit the needs and search intent of potential customers.

Voice Search Optimization

Voice-activated devices are increasingly being used to perform searches and online shopping. As voice search is typically more conversational and question-based, you can use IoT data to understand the common phrases or questions consumers ask these devices. This can help you optimize your product descriptions, FAQs, and even blog posts to align with the natural language used in voice searches.

Local SEO and IoT

The "near me" search query is incredibly popular, thanks in part to IoT devices with geolocation capabilities. People use their smartphones or smartwatches to find the nearest restaurant, gas station, or store. If you have a brick-and-mortar store in addition to your online shop, IoT data can help you target local SEO more effectively by integrating local keywords and ensuring your Google My Business listing is up-to-date.

IoT and Page Experience

With IoT, user experience can go beyond the digital interface to incorporate real-world interactions. For example, a smart fridge could remind users to order more milk, directing them to your online grocery store. If your website isn’t optimized for speed and experience, you could lose these high-intent users. Incorporating IoT insights into your SEO strategy can help you anticipate these needs and optimize your site accordingly.

Real-Time Personalization

IoT devices can collect data in real-time, offering insights into user behaviour that can be immediately acted upon. Imagine someone just completed a workout on their smart treadmill. They might then search for protein shakes or workout gear. With real-time data, you could offer timely discounts or suggestions, personalized to the user's immediate needs, all while improving your SEO through higher user engagement and lower bounce rates.

Wrapping It Up

IoT and SEO may seem like different arenas, but they are more interconnected than you'd think. By adopting a holistic approach that marries the insights from IoT devices with your SEO strategy, you can significantly improve your eCommerce site's performance. From optimizing for voice search and improving local SEO to real-time personalization and superior user experience, the opportunities are endless.

The Internet of Things (IoT) continues to revolutionize industries, and Microsoft Azure IoT is at the forefront of this transformation. With its robust suite of services and features, Azure IoT enables organizations to connect, monitor, and manage their IoT devices and data effectively. In this blog post, we will explore the latest trends and use cases of Azure IoT in 2023, showcasing how it empowers businesses across various sectors.

Edge Computing and AI at the Edge:

As the volume of IoT devices and the need for real-time analytics increases, edge computing has gained significant momentum. Azure IoT enables edge computing by seamlessly extending its capabilities to the edge devices. In 2023, we can expect Azure IoT to further enhance its edge computing offerings, allowing organizations to process and analyze data closer to the source. With AI at the edge, businesses can leverage machine learning algorithms to gain valuable insights and take immediate actions based on real-time data.

Edge Computing and Real-time Analytics:

As IoT deployments scale, the demand for real-time data processing and analytics at the edge has grown. Azure IoT Edge allows organizations to deploy and run cloud workloads directly on IoT devices, enabling quick data analysis and insights at the edge of the network. With edge computing, businesses can reduce latency, enhance security, and make faster, data-driven decisions.

Industrial IoT (IIoT) for Smart Manufacturing:

Azure IoT is poised to play a crucial role in the digital transformation of manufacturing processes. IIoT solutions built on Azure enable manufacturers to connect their machines, collect data, and optimize operations. In 2023, we anticipate Azure IoT to continue empowering smart manufacturing by offering advanced analytics, predictive maintenance, and intelligent supply chain management. By harnessing the power of Azure IoT, manufacturers can reduce downtime, enhance productivity, and achieve greater operational efficiency.

Connected Healthcare:

In the healthcare industry, Azure IoT is revolutionizing patient care and operational efficiency. In 2023, we expect Azure IoT to drive the connected healthcare ecosystem further. IoT-enabled medical devices, remote patient monitoring systems, and real-time data analytics can help healthcare providers deliver personalized care, improve patient outcomes, and optimize resource allocation. Azure IoT's robust security and compliance features ensure that sensitive patient data remains protected throughout the healthcare continuum.

Smart Cities and Sustainable Infrastructure:

As cities strive to become more sustainable and efficient, Azure IoT offers a powerful platform for smart city initiatives. In 2023, Azure IoT is likely to facilitate the deployment of smart sensors, intelligent transportation systems, and efficient energy management solutions. By leveraging Azure IoT, cities can enhance traffic management, reduce carbon emissions, and improve the overall quality of life for their residents.

Retail and Customer Experience:

Azure IoT is transforming the retail landscape by enabling personalized customer experiences, inventory optimization, and real-time supply chain visibility. In 2023, we can expect Azure IoT to continue enhancing the retail industry with innovations such as cashier-less stores, smart shelves, and automated inventory management. By leveraging Azure IoT's capabilities, retailers can gain valuable insights into customer behavior, streamline operations, and deliver superior shopping experiences.

AI and Machine Learning Integration:

Azure IoT integrates seamlessly with Microsoft's powerful artificial intelligence (AI) and machine learning (ML) capabilities. By leveraging Azure IoT and Azure AI services, organizations can gain actionable insights from their IoT data. For example, predictive maintenance algorithms can analyze sensor data to detect equipment failures before they occur, minimizing downtime and optimizing operational efficiency.

Enhanced Security and Device Management:

In an increasingly interconnected world, security is a top priority for IoT deployments. Azure IoT provides robust security features to protect devices, data, and communications. With features like Azure Sphere, organizations can build secure and trustworthy IoT devices, while Azure IoT Hub ensures secure and reliable device-to-cloud and cloud-to-device communication. Additionally, Azure IoT Central simplifies device management, enabling organizations to monitor and manage their IoT devices at scale.

Industry-specific Solutions:

Azure IoT offers industry-specific solutions tailored to the unique needs of various sectors. Whether it's manufacturing, healthcare, retail, or transportation, Azure IoT provides pre-built solutions and accelerators to jumpstart IoT deployments. For example, in manufacturing, Azure IoT helps optimize production processes, monitor equipment performance, and enable predictive maintenance. In healthcare, it enables remote patient monitoring, asset tracking, and patient safety solutions.

Integration with Azure Services:

Azure IoT seamlessly integrates with a wide range of Azure services, creating a comprehensive ecosystem for IoT deployments. Organizations can leverage services like Azure Functions for serverless computing, Azure Stream Analytics for real-time data processing, Azure Cosmos DB for scalable and globally distributed databases, and Azure Logic Apps for workflow automation. This integration enables organizations to build end-to-end IoT solutions with ease.

Conclusion:

In 2023, Azure IoT is set to drive innovation across various sectors, including manufacturing, healthcare, cities, and retail. With its robust suite of services, edge computing capabilities, and AI integration, Azure IoT empowers organizations to harness the full potential of IoT and achieve digital transformation. As businesses embrace the latest trends and leverage the diverse use cases of Azure IoT, they can gain a competitive edge, improve operational efficiency, and unlock new opportunities in the connected world.

About Infysion

We work closely with our clients to help them successfully build and execute their most critical strategies. We work behind-the-scenes with machine manufacturers and industrial SaaS providers, to help them build intelligent solutions around Condition based machine monitoring, analytics-driven Asset management, accurate Failure predictions and end-to-end operations visibility. Since our founding 3 years ago, Infysion has successfully productionised over 20+ industry implementations, that support Energy production, Water & electricity supply monitoring, Wind & Solar farms management, assets monitoring and Healthcare equipment monitoring.

We strive to provide our clients with exceptional software and services that will create a meaningful impact on their bottom line.

Visit our website to learn more about success stories, how we work, Latest Blogs and different services we do offer!

Cloud-based motor monitoring as a service is revolutionizing the way industries manage and maintain their critical assets. By leveraging the power of the cloud, organizations can remotely monitor motors, analyze performance data, and predict potential failures. However, as this technology continues to evolve, several challenges emerge that need to be addressed for successful implementation and operation. In this blog post, we will explore the top challenges faced in cloud-based motor monitoring as a service in 2023.

Data Security and Privacy:

One of the primary concerns in cloud-based motor monitoring is ensuring the security and privacy of sensitive data. As motor data is transmitted and stored in the cloud, there is a need for robust encryption, authentication, and access control mechanisms. In 2023, organizations will face the challenge of implementing comprehensive data security measures to protect against unauthorized access, data breaches, and potential cyber threats. Compliance with data privacy regulations, such as GDPR or CCPA, adds an additional layer of complexity to this challenge.

Connectivity and Network Reliability:

For effective motor monitoring, a reliable and secure network connection is crucial. In remote or industrial environments, ensuring continuous connectivity can be challenging. Factors such as signal strength, network coverage, and bandwidth limitations need to be addressed to enable real-time data transmission and analysis. Organizations in 2023 will need to deploy robust networking infrastructure, explore alternative connectivity options like satellite or cellular networks, and implement redundancy measures to mitigate the risk of network disruptions.

Scalability and Data Management:

Cloud-based motor monitoring generates vast amounts of data that need to be efficiently processed, stored, and analyzed. In 2023, as the number of monitored motors increases, organizations will face challenges in scaling their data management infrastructure. They will need to ensure that their cloud-based systems can handle the growing volume of data, implement efficient data storage and retrieval mechanisms, and utilize advanced analytics and machine learning techniques to extract meaningful insights from the data.

Integration with Existing Systems:

Integrating cloud-based motor monitoring systems with existing infrastructure and software can pose significant challenges. In 2023, organizations will need to ensure seamless integration with their existing enterprise resource planning (ERP), maintenance management, and asset management systems. This includes establishing data pipelines, defining standardized protocols, and implementing interoperability between different systems. Compatibility with various motor types, brands, and communication protocols also adds complexity to the integration process.

Cost and Return on Investment:

While cloud-based motor monitoring offers numerous benefits, organizations must carefully evaluate the cost implications and expected return on investment (ROI). Implementing and maintaining the necessary hardware, software, and cloud infrastructure can incur significant expenses. Organizations in 2023 will face the challenge of assessing the financial viability of cloud-based motor monitoring, considering factors such as deployment costs, ongoing operational expenses, and the potential savings achieved through improved motor performance, reduced downtime, and optimized maintenance schedules.

Connectivity and Reliability:

Cloud-based motor monitoring relies heavily on stable and reliable internet connectivity. However, in certain remote locations or industrial settings, maintaining a consistent connection can be challenging. The availability of high-speed internet, network outages, or intermittent connections may impact real-time monitoring and timely data transmission. Service providers will need to address connectivity issues to ensure uninterrupted monitoring and minimize potential disruptions.

Scalability and Performance:

As the number of monitored motors increases, scalability and performance become critical challenges. Service providers must design their cloud infrastructure to handle the growing volume of data generated by motor sensors. Ensuring real-time data processing, analytics, and insights at scale will be vital to meet the demands of large-scale motor monitoring deployments. Continuous optimization and proactive capacity planning will be necessary to maintain optimal performance levels.

Integration with Legacy Systems:

Integrating cloud-based motor monitoring with existing legacy systems can be a complex undertaking. Many organizations have legacy equipment or infrastructure that may not be inherently compatible with cloud-based solutions. The challenge lies in seamlessly integrating these disparate systems to enable data exchange and unified monitoring. Service providers need to offer flexible integration options, standardized protocols, and compatibility with a wide range of motor types and manufacturers.

Data Analytics and Actionable Insights:

Collecting data from motor sensors is only the first step. The real value lies in extracting actionable insights from this data to enable predictive maintenance, identify performance trends, and optimize motor operations. Service providers must develop advanced analytics capabilities that can process large volumes of motor data and provide meaningful insights in a user-friendly format. The challenge is to offer intuitive dashboards, anomaly detection, and predictive analytics that empower users to make data-driven decisions effectively.

Conclusion:

Cloud-based motor monitoring as a service offers tremendous potential for organizations seeking to optimize motor performance and maintenance. However, in 2023, several challenges need to be addressed to ensure its successful implementation. From data security and connectivity issues to scalability, integration, and advanced analytics, service providers must actively tackle these challenges to unlock the full benefits of cloud-based motor monitoring. By doing so, organizations can enhance operational efficiency, extend motor lifespan, and reduce costly downtime in the ever-evolving landscape of motor-driven industries.

Connected devices in the medical field bring a multitude of benefits, including improved patient care, enhanced diagnostics, and streamlined healthcare processes. However, the complexity associated with these devices is a significant consideration. Here, we explore the intricacies involved in the realm of connected medical devices.

First and foremost, interoperability is a critical challenge. Medical environments comprise various devices from different manufacturers, each with its own communication protocols and data formats. Ensuring seamless connectivity and data exchange between these devices necessitates standardized interfaces and robust interoperability frameworks.

Data security and privacy are paramount in the medical domain. Connected devices generate and transmit sensitive patient data, including personal health information and vital signs. Safeguarding this information from unauthorized access, data breaches, and cyber threats requires robust encryption, authentication mechanisms, and strict adherence to regulatory standards like the Health Insurance Portability and Accountability Act (HIPAA)

The complexity also arises from the diverse range of connected devices used in healthcare. From wearable sensors to implantable devices, infusion pumps to remote monitoring systems, each device has specific requirements, connectivity options, and integration challenges. Managing this ecosystem of devices, ensuring seamless communication, and maintaining their functionality demand specialized expertise and effective device management solutions.

Furthermore, regulatory compliance adds another layer of complexity. Connected medical devices must meet rigorous standards to ensure safety, accuracy, and reliability. Regulatory bodies, such as the U.S. Food and Drug Administration (FDA), closely scrutinize these devices for adherence to quality standards, clinical validation, and risk mitigation measures.

Additionally, healthcare organizations need to navigate the complexity of data analytics and actionable insights. Connected devices generate vast amounts of data that must be processed, analyzed, and transformed into meaningful information for healthcare professionals. Extracting valuable insights from this data necessitates advanced analytics algorithms, machine learning techniques, and data visualization tools.

Overcoming the challenges requires collaboration among manufacturers, healthcare providers, and regulatory bodies to develop robust standards, innovative solutions, and best practices that ensure safe, secure, and effective utilization of connected devices to revolutionize patient care.

We all know how IoT has revolutionized the way we interact with the world. IoT devices are now ubiquitous, from smart homes to industrial applications. A significant portion of these devices are Wireless Sensor Networks (WSNs), which are a key component of IoT systems. However, designing and implementing WSNs presents several challenges for embedded engineers. In this article, we discuss some of the significant challenges that embedded engineers face when working with WSNs.

WSNs are a network of small, low-cost, low-power, and wirelessly connected sensor nodes that can sense, process, and transmit data. These networks can be used in a wide range of applications such as environmental monitoring, healthcare, industrial automation, and smart cities. WSNs are typically composed of a large number of nodes, which communicate with each other to gather and exchange data. The nodes are equipped with sensors, microprocessors, transceivers, and power sources. The nodes can also be stationary or mobile, depending on the application.

One of the significant challenges of designing WSNs is the limited resources of the nodes. WSNs are designed to be low-cost, low-power, and small, which means that the nodes have limited processing power, memory, and energy. This constraint limits the functionality and performance of the nodes. Embedded engineers must design WSNs that can operate efficiently with limited resources. The nodes should be able to perform their tasks while consuming minimal power to maximize their lifetime.

Another challenge of WSNs is the limited communication range. The nodes communicate with each other using wireless radio signals. However, the range of the radio signals is limited, especially in indoor environments where the signals are attenuated by walls and other obstacles. The communication range also depends on the transmission power of the nodes, which is limited to conserve energy. Therefore, embedded engineers must design WSNs that can operate reliably in environments with limited communication range.

WSNs also present a significant challenge for embedded engineers in terms of data management. WSNs generate large volumes of data that need to be collected, processed, and stored. However, the nodes have limited storage capacity, and transferring data to a centralized location may not be practical due to the limited communication range. Therefore, embedded engineers must design WSNs that can perform distributed data processing and storage. The nodes should be able to process and store data locally and transmit only the relevant information to a centralized location.

Security is another significant challenge for WSNs. The nodes in WSNs are typically deployed in open and unprotected environments, making them vulnerable to physical and cyber-attacks. The nodes may also contain sensitive data, making them an attractive target for attackers. Embedded engineers must design WSNs with robust security features that can protect the nodes and the data they contain from unauthorized access.

The deployment and maintenance of WSNs present challenges for embedded engineers. WSNs are often deployed in harsh and remote environments, making it difficult to access and maintain the nodes. The nodes may also need to be replaced periodically due to the limited lifetime of the power sources. Therefore, embedded engineers must design WSNs that are easy to deploy, maintain, and replace. The nodes should be designed for easy installation and removal, and the network should be self-healing to recover from node failures automatically.

Final thought; WSNs present significant challenges for embedded engineers, including limited resources, communication range, data management, security, and deployment and maintenance. Addressing these challenges requires innovative design approaches that can maximize the performance and efficiency of WSNs while minimizing their cost and complexity. Embedded engineers must design WSNs that can operate efficiently with limited resources, perform distributed data processing and storage, provide robust security features, and be easy to deploy

In recent days, neural networks have become a topic for discussion. But the question still needs to be solved- How can it affect our world today and tomorrow?

The global neural network market's compound annual growth rate (CAGR) is expected to be 26.7% from 2021 to 2030. This means that new areas of application for them might appear soon. The Internet of Things that is IoT, is today's most fascinating and required technological solution for business. Around 61% of companies utilize IoT platforms, and we can anticipate the integration of neural networks into enterprise IoT solutions. This anticipation raises many questions, like what gets such collaboration and how to prepare it. Can we optimize the IoT ecosystem using neural networks, and who will approach such solutions?

What do you understand by a neural network, and how is it beneficial for enterprise IoT?

An artificial neural network that is ANN is a network of artificial neurons striving to simulate the analytical mechanisms taken by the human brain. This type of artificial intelligence includes a range of algorithms that can "learn" from their own experience and improve themselves, which is very different from classical algorithms that are programmed to resolve only specific tasks. Thus, with time, the neural network will remain pertinent and keep on improving.

With the proper implementation, enterprise internet of things (EIoT) and ANN can offer the business the most valuable things: precise analytics and forecasts. In general, it is not possible to compare both. Enterprise IoT is a system that needs software for data analysis, whereas ANN is a component that needs a large amount of data to be operational. Their team naturally controls the analytical tasks; therefore, high-level business tasks are performed most effectively, reducing costs, automating processes, finding new revenue sources, etc.

In the Internet of Things ecosystem, neural networks help in two areas above all:

- Data acquisition via ANN-based machine vision

- Advanced-data analysis

If it needs significant investments to execute ANN in big data analytics solutions, neural network image processing can decrease the cost of the IoT solution. Thus, neural networks improve enterprise IoT solutions, enhance their value, and speed up global adoption.

Which solutions within enterprise IoT can be enhanced using neural networks?

IoT-based visual control

The IoT ecosystem begins with data collection. Data quality impacts the accuracy of the ultimate prediction. If you implement visual control in your production processes, neural networks can boost the quality of products by superseding outdated algorithms. Besides this, they will optimize the EIoT solution. Conventional machine vision systems are pricey as they require the highest resolution cameras to catch minor defects in a product. They come with complex specific software that fails to respond to immediate changes.

Neural networks within machine vision systems can:

- Diminish camera requirements

- Self-learn on your data

- Automate high-speed operations

Indeed, industrial cameras use large-format global shutter sensors having high sensitivity and resolution to develop the highest quality images. Nevertheless, a well-trained ANN starts to identify images with time. It allows them to reduce the technical needs for the camera and ultimately cuts the final cost of the enterprise IoT implementation. You cannot compromise the quality of images to detect small components like parts in circuit boards; however, it is manageable for printing production, completeness checking, or food packaging.

After training, neural networks use massive amounts of data to identify objects from the images. It enables you to customize the EIoT solution and train the ANN to operate specifically with your product by processing your images.

For example, convolutional neural networks are utilized actively in the healthcare industry to detect X-rays and CT scans. The outcome offered by such custom systems is more precise than conventional ones. The capability to process information at high speeds permits the automation of production processes. When the problem or defect is caught, neural networks promptly report it to the operator or launch an intelligent reaction, like automating sorting. Hence, it allows real-time detection and rejection of defective production.

An exclusive example of how ANN is utilized for edge and fog computing. As per PSA, a neural network executed in a machine vision system permits lowering the number of defects by 90% in half a year, whereas production costs are decreased by 30%. Prospective areas for ANN in IoT visual control are quality assurance, sorting, production, collecting, marking, traffic control, and ADAS.

Big data advanced analytics for enterprise IoT:

Today, neural networks allow businesses to grab advantages like predictive maintenance, new revenue flows, asset management, etc. It is possible via deep neural networks (DNN) and the deep Learning (DL) method involving multiple layers for data processing. They detect hidden data trends and valuable information from a significant dataset by employing classification, clustering, and regression. It results in effective business solutions and the facilitation of business applications.

In comparison to traditional models, DL manages with the attributes that are expected for IoT data:

- Assess the time of taking measurements

- Resist the high noise of the enterprise IoT data

- Conduct accurate real-time analysis

- Determine heterogeneous and discordant data

- Process a large amount of data

In practice, this implies that you don't require middle solutions to deliver and sort the data in the cloud or to analyze them in real-time. For example, full-cycle metallurgical enterprises can execute one solution to analyze the variable and unstructured data from metal mining, smelting, and final manufacturing products. Airplanes generate about 800TB of data per hour, making it impossible to process it all ideally using conventional analytical systems.

Today, DNN models are successful in the following enterprise IoT applications.

Healthcare:

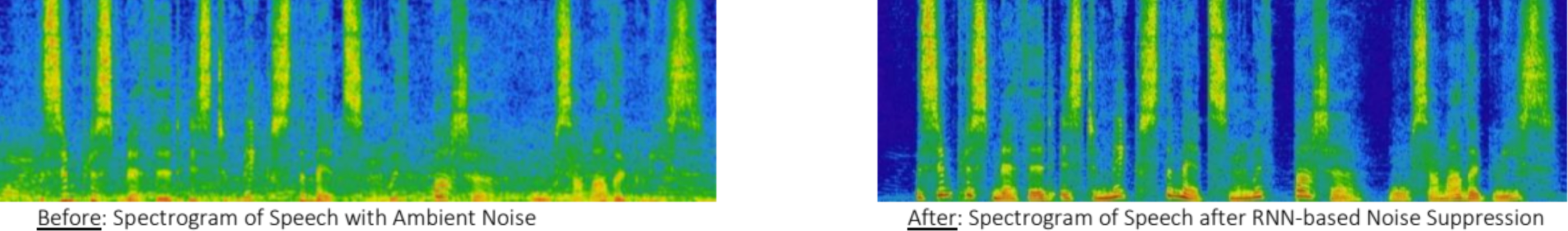

Today, it has become easy to predict disease using AI-based IoT systems, and this technology is developing for further improvements. For instance, the latest invention based on the neural network can detect the risk of heart attacks by up to 94.8%. DNN is also helpful in disease detection: the spectrogram of a person's voice received using IoT devices can identify voice pathologies after DNN processing. In general, ANN-based IoT health monitoring systems' accuracy is estimated to be above 85%.

Power consumption:

DL systems in the enterprise Internet of Things have provided results in power demand prediction based on power price forecasting, consumption data, anomaly, power theft detection, and leak detection. Smart meter data analysis permits you to calculate consumption, determine the unusual usage of electricity, and predict with an accuracy of more than 95%, which will help you to adjust energy consumption.

Manufacturing:

Neural networks help to use the most demanded IoT service among manufacturers properly- predictive equipment maintenance. It was ascertained to be a workable practice for mechanical and electrical systems. This network provides accurate real-time status monitoring and predicts proper life rest. Another best example is the recognition of employee activity by taking readings and following in-depth analysis.

Transportation & Logistics:

Deep Learning has made smart transportation systems possible. It offers better traffic congestion management by processing travel time, speed, weather, and occupational parking forecasting. Analytical reports based on vehicle data help to discover dangerous driving and possible issues before the failure happens.

As we know, the previous industries generate heterogeneous data. Therefore, the potential of ANN analytics within EIoT will be unlocked for multiple complicated systems.

When to consider ANN for enterprise IoT:

Till now, research in the field of ANNs been very active, and we cannot foretell all the advantages or pitfalls these solutions will convey. No doubt, neural networks find out correlations, models, and trends better than other algorithms. The IoT ecosystem's data will become more extensive, complex, and diverse with time. So, the development of neural networks is the future of IoT.

For now, we can look into the following features of neural networks for enterprise IoT:

- They suit the IoT ecosystem architecture, substituting alternative solutions with significant advantages.

- Essential for industrial image processing.

- Progressive ANN-based data analytics gets the high-level business value of the enterprise IoT solutions – improves productivity, and exactness, boosts sales, and produces informed business decisions.

- Training the ANN requires time and expenditure but will become fully customizable.

- We cannot conclude it is an affordable solution, but the advantages are priceless if the IoT ecosystem is executed accurately.

Therefore, if you are provided with a neural network as one of the opportunities for executing your idea within the IoT ecosystem, give it a chance. You never know, this solution will become a must-have in the coming years.

The wireless module is a modular product of digital data transmission radio. It refers to a high-performance professional data transmission radio module realized with the help of single-chip microcomputer technology and radio technology. The wireless transceiver module is mainly used to control wireless data transmission and reception through a single-chip microcomputer. Generally, it is FSK, GFSK modulation mode. If it is divided by operating frequency, there are 170MHz, 230MHz, 315MHz, 433MHz, 868MHz, 915MHz, 2.4GHz and so on.

The Internet of Things is an important part of the new generation of information technology and an important stage of development in the "informatization" era. The Internet of Things is a network that extends and expands its user end to any item and item for information communication and exchange to achieve intelligence.

With the increasing number of IoT product forms, on the one hand, module prices will continue to fall; on the other hand, IoT modules will continue to develop in a diversified direction to meet the functional requirements of more and more different types of equipment. In the next few years, wireless communication modules for the Internet of Things will develop in the direction of more integration and miniaturization, and more and more chips and functions will be integrated into the IoT module.

From the current development situation, the typical applications of wireless modules in the field of Internet of Things are as follows:

Industrial applications

Industry is an important area for wireless module applications in the Internet of Things. Various types of terminal sensors with environmental awareness capabilities communicate data collected through wireless modules to achieve intelligent monitoring and intelligent control in the production process. This greatly improves production efficiency, improves product quality, reduces production costs, and reduces traditional industrial Ascension to a new stage of smart industry.

For example, parts processing enterprises use various sensors and wireless modules to achieve real-time monitoring of the width, thickness, and temperature of processed parts during the production process, thereby improving production efficiency and optimizing production processes.

Agricultural applications

The application of the wireless module in the agricultural field is to collect the temperature, humidity signals and environmental parameters such as light, soil temperature, leaf surface humidity, etc. in the greenhouse in real time, and realize the automatic stop or start of specified equipment through the Internet of Things technology. It can be processed at any time according to user needs, providing a scientific basis for automatic monitoring of agricultural ecological information, automatic control of the environment, and intelligent management. The temperature and humidity signals are collected through sensors, and the data is transmitted through the wireless module to achieve remote control of the temperature and humidity in the greenhouse, and record the scene conditions to ensure the temperature and humidity balance in the greenhouse.

Smart home applications

Smart home is the automation of various home devices (such as audio and video equipment, network appliances, curtain control, air conditioning control, lighting systems, security systems, etc.) through smart home network networking. Through wireless networks, remote control of home devices can be realized. . Smart home is an important area for wireless module applications. Compared with ordinary homes, smart homes not only provide comfortable, pleasant and high-quality home living spaces, and realize more intelligent home security systems; they also transform the home environment from the original passive still structure into a tool with active wisdom, providing a full range of tools Information interaction function makes you feel more comfortable and worry-free.

Smart medical applications

The intelligent medical system uses simple and practical home medical sensing equipment to monitor the physiological indicators of the patients or the elderly in the home in real time, and transmits the generated physiological indicator data to the caregiver or the relevant medical unit through the wireless module. According to customer needs, relevant value-added services have now begun to be provided, such as emergency call assistance services and expert consulting services.

Smart city security application

Smart city security system is a unified monitoring of the safety of the city. The electronic equipment equipped with wireless modules is used to network decentralized and independent image collection points to remotely monitor, transmit, store, and manage in real time, to achieve unified monitoring, unified storage and unified management of city security, and to provide city management and builders with A new, intuitive, and extended audiovisual management tool.

Environmental monitoring applications

The environmental monitoring system monitors the water quality of the earth's surface water in real time, thereby realizing timely grasp of the water quality status of the main sections of the main river basin, early warning and forecast of major or river basin water pollution accidents, resolving water pollution accident disputes across administrative regions, and monitoring the total Implementation of control system. The West Lake Environmental Monitoring Project provides water quality data of West Lake to environmental protection departments through various monitoring wireless modules installed in the West Lake area, monitors the water quality of West Lake waters in real time, and reports the data of monitoring points to relevant management departments via the Internet. .

Intelligent transportation applications

Intelligent transportation system is the real-time monitoring and management of the car's position and speed, image information inside and outside the car, and other vehicle parameters, effectively meeting the various needs of vehicle owners for vehicle management. The wireless video surveillance system for the bus industry uses the wireless video surveillance and GPS positioning functions of on-board equipment to monitor the running status of the bus in real time. The intelligent bus station interacts with the data of the electronic station board through the media distribution center, and realizes the functions of public transport dispatch information data and multimedia data. It can also use the electronic station board to realize the function of advertising.

The Internet of Things network of interconnected devices such as sensors, gateways, and computers that transfer the data over a wireless network eliminates the need for human intervention. IoT devices can be remotely tracked, and controlled in real-time. It also enables users to connect and interact with others over the internet. The applications of IoT are tremendous and it can be found in every part of human life, ranging from smartwatches to self-driving cars.

What Is IoT Device Management?

IoT device management refers to the ability to remotely accessing, monitoring, tracking and managing the functionality of IoT devices in order to ensure the deployed devices are secure, up to date and compliant. Here’s a breakdown of the reasons why businesses need an IoT device management platform:

- Accelerate time to market

One of the biggest perks of the IoT device management platform is that it helps developers to reduce the time frame of product development and testing, thereby enabling them to release products to market on time. Furthermore, streamlining and automating network and device management tasks enables businesses to concentrate on their core competencies while lowering costs.

- Secure device on and off boarding

A smart device is not, and should not be, automatically connected to an IoT network. A secure approach is required to configure and add only authorized devices to the network architecture, and a network and device management tool makes this simple and straightforward. End nodes can be authenticated and secure communications established via a web interface by registering and attaching them to the authorized base station using their network keys and identification credentials. Only after the node has completed the onboarding process it will be allowed to join the network and securely transmit data using network-level encryption. Similarly, if deployed nodes are no longer required, they can be easily offboarded from the web UI – without having to travel to the field.

- Streamline network monitoring and troubleshooting

IoT device management platform enables firms to gain a top to bottom view of all registered nodes, network traffic and their status in a single interface. It acts as a central hub for data aggregation across base stations in a network with multiple base stations. This is especially useful for monitoring and identifying unexpected network and device problems. Businesses can quickly identify and determine the root causes of bottlenecks with real-time visibility into incoming data, battery level, and keep-alive messages from individual nodes. For example, if a node fails to deliver messages on a regular basis, the radio traffic may be overloaded. If, on the other hand, it completely disconnects from the network and stops sending messages, it could be due to a hardware or firmware flaw. Similarly, by continuously monitoring battery levels, firms can schedule maintenance for multiple devices at the same time, saving time and money.

- Simplifies downstream application deployment

IoT device management platform serves as a link between the edge network, downstream data servers of users and enterprise applications. Using protocols like MQTT and API calls, a versatile IoT device management solution allows for easy integration with any backend system, whether on-premises or in the cloud. As a result, firms can easily deploy and scale IoT applications to meet changing business needs, whether by adding new devices to an existing app or connecting to a new analytics platform. It also enables businesses to gain a better view of all current integrations and applications from a single window thereby simplifying the management of an entire IoT project.

- Eliminate security risks

Considering the ever-increasing complexity of cyber-attacks, it is critical to equip connected IoT network components such as base stations and routers with the most up-to-date security features. A manual approach cannot keep up with the demand for continuous and timely updates to these critical network infrastructures, particularly those deployed remotely - Here comes the need for an IoT device management tool. It will enable businesses to update operating systems automatically and run security updates from afar, helping them to save money while also ensuring their remote base stations are well-prepared against malicious attacks. Furthermore, round-the-clock monitoring of the network assists firms in the early detection of unusual patterns, such as an increase in data traffic, which could indicate a breach and eliminate security hazards.

Conclusion

The advancements in IoT and AI services have made it critical for businesses to rely on efficient and secure methods to manage and control their networks and devices at scale. An IoT device management platform helps businesses to track, manage and gain real-time insights into all devices and stay on top of their deployment. When combined with a robust wireless solution, it enables firms to seamlessly expand their IoT network and solutions at minimal cost and complexity.

The past several years have seen a huge growth in the number of companies offering IoT Platforms. The market research firm IoT Analytics reported 613 companies offering IoT platforms in 2021! This is a mind-blowing number. The IoT platforms vary widely in capabilities but typically focus on one or more of the building blocks of IoT systems – physical devices, internet connectivity, and digital services. In one way or another, they provide software (or in some cases hardware too) that gives companies a head-start when building IoT systems. There are so many companies offering platforms that it is nearly impossible to keep up with all of them.

Charting the right path, avoiding pitfalls, maximizing your success.

If you are getting into IoT and not familiar with IoT platforms, you might be asking yourself questions like – What makes up an IoT platform? What advantages could they have for my company? How do I select an IoT platform?

Let’s tackle these questions one by one.

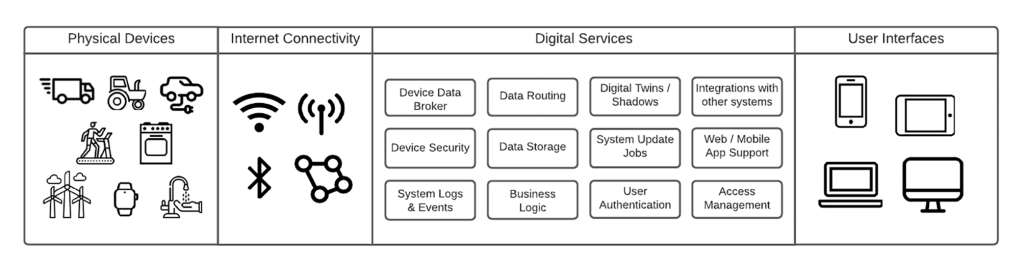

What makes up an IoT platform?

Features

True IoT platforms typically provide the following features:

- Digital services running in the cloud that physical devices connect to

- Software that runs on devices that communicates with the digital services

- A framework or schema for data messaging and remote command & control of devices

- Security infrastructure to handle device registration, authentication, security credential management

- Tools and methods for updating device firmware over-the-air (OTA)

- Web dashboards for viewing the state of devices and interacting with the system

IoT platforms may or may not also provide other features, including:

- Analytics tools and dashboards

- Digital twins or shadows

- Application deployment orchestration

- Machine learning orchestration

- Rules engines

- Fleet management tools

- Integrations to other services

- Gateway or hub support for bridging devices to the cloud

- Cellular network plans for devices

- Web or mobile application interfaces and templates

Example Elements of an IoT Platform

Types of IoT Platforms

IoT platforms are not all the same. Their features and target use-cases vary a lot. However, at a high level, they can be grouped into two main categories.

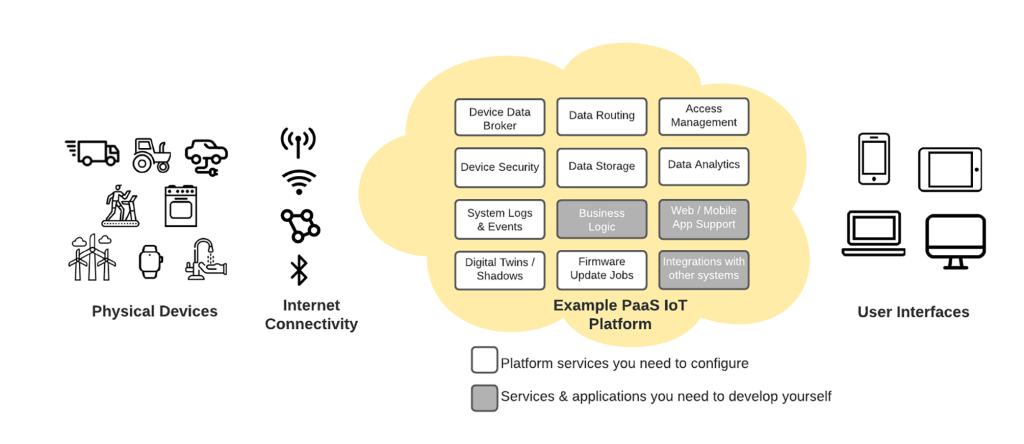

Platform as a Service (PaaS) – Offered by the big cloud service providers

PaaS platforms provide building blocks to do most things an IoT system needs, but it is up to you to write the custom code that connects it all together. With a PaaS provider, you don’t have to worry about underlying server hardware, but you have to compose their services into a working architecture and manage the deployment of applications that use their services. This is more work but allows more flexibility and the opportunity to customize the system to your needs. Ongoing costs of a PaaS IoT platform are typically lower than a SaaS, but expertise is required to ensure correct usage patterns to avoid larger costs. The big cloud providers all offer PaaS IoT platforms. This includes Amazon Web Services (AWS), Microsoft Azure, and Google Cloud Platform (GCP).

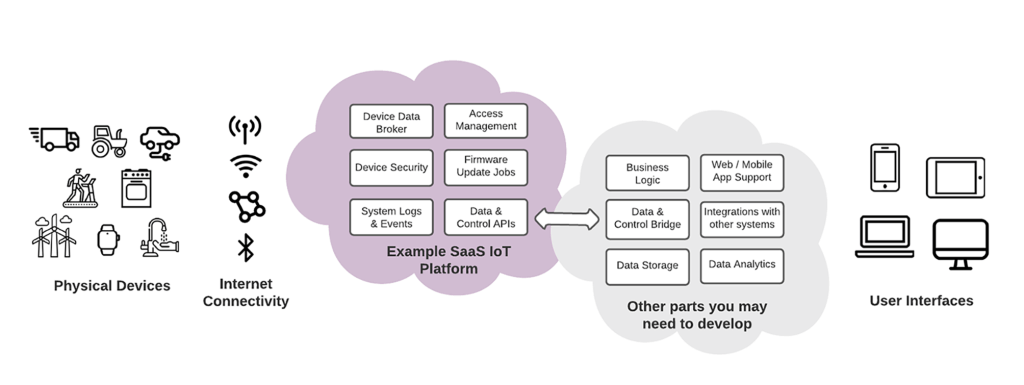

Software as a Service (SaaS) – Offered by numerous software vendors, large and small

With a SaaS provider, you get access to use the software application they deploy and manage for you. Or you can license it and deploy it yourself. SaaS platforms typically provide some configurability and integrations with other systems. There is much less work on the cloud side as this is mostly taken care of for you. However, you are limited to the features that the IoT platform provider offers. You may need to invest more in bridging the platform to your other systems. Depending on your use case, a SaaS may provide more advanced features out-of-the-box than a PaaS. Ongoing costs are likely to be higher with SaaS IoT platforms. Examples of SaaS IoT platform providers include Pelion, Losant, Friendly Technologies, Software AG, Blynk, Particle, ThingsBoard, and Golioth.

What advantages could they have for my company?

Benefits of IoT Platforms – There are a lot.

The goal of IoT platforms is to provide a foundation for product-makers to build IoT solutions on top of. IoT platforms take care of all the fundamental features that all solutions need (e.g. “the plumbing”), so you can focus on adding value with the differentiating features that you add on top. Users of IoT platforms get a huge benefit from economies of scale – especially if using the most popular platforms. This translates into improved security, more robust services, and lower costs. For these reasons, we always recommend using an IoT platform.

How do I select an IoT platform?

The Big Question – Should you use a PaaS or SaaS?

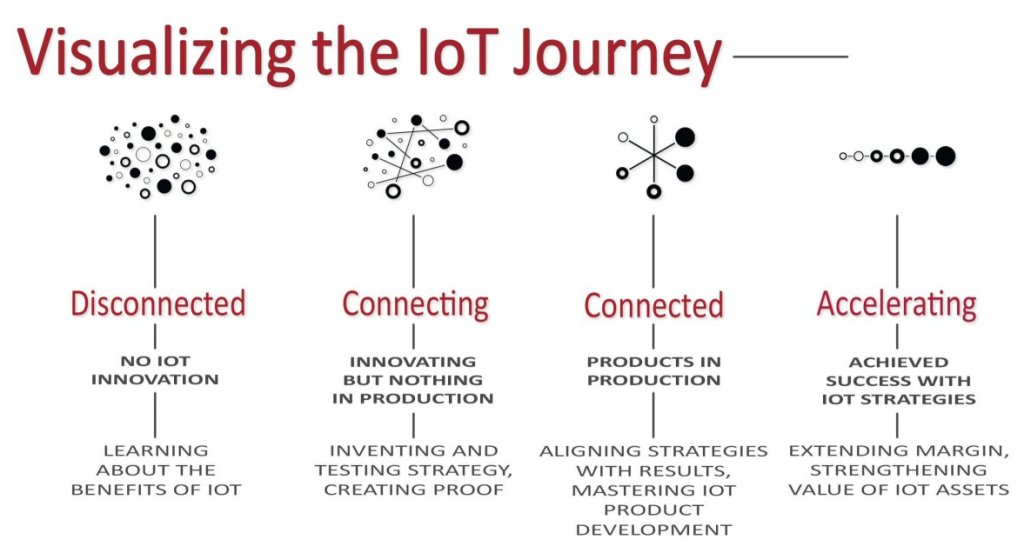

At SpinDance, we believe in lean and agile business principles. This usually translates into taking a staged approach and focusing on different priorities in each stage. IoT is a journey, not a destination. We have seen the most success when companies tackle each of their challenges in stages, don’t try to do too much too quickly, and don’t lock themselves into long-term decisions too early. Choosing whether to use a PaaS or Saas depends on the stage you are in along your IoT journey.

Our Answer – It depends on your stage in your IoT journey.

If you are just starting on your IoT journey…

In the disconnected stage your main goals are to learn what technology can do for you, develop a vision for your new product or service with that knowledge, and evaluate your vision based on customer input. At this stage, you shouldn’t be worried too much about scale or efficiency. You need to nail down the problem you want to solve and the solution you propose to solve it with. Ash Maurya, entrepreneur and author of Running Lean, says that “Building a successful product is fundamentally about risk mitigation.” To evaluate and reduce your risk, you need to test your assumptions.

We often recommend building Proof of Concepts and Prototypes in this stage. These experiments are crucial to help you quickly validate the feasibility, desirability, and viability of your plans. They also help rally your organization and potential customers around new possibilities.

SaaS IoT platforms have their most advantage in this stage. They can help you get devices connected and data flowing quickly because they typically have more features ready out-of-the-box. However, since your knowledge about the future is limited at this stage, we recommend you avoid long-term commitments so you don’t get stuck with a solution that doesn’t work for you down the road.

If you are working on your first connected product…

In the connecting stage, you should have some confidence in your problem-market fit and you should have a better idea of what benefits IoT can bring to your business. Now you need to build a system to deal with the rigors of production. You also need to adapt your organization to support your new product or service.

We recommend shifting your focus to creating robust experiences for your customers spanning across the physical devices and digital interfaces they interact with. You need to consider the other parts of the system such as mobile applications, web applications, database storage, operations dashboards, etc that you’ll need for your customers and your internal teams to interact with the system.

PaaS IoT platforms start to have a strong advantage in this stage. More often than not, we see the needs of the company outstretch the features provided by a SaaS. Therefore, there is a need to augment the capabilities of the SaaS platform or bridge it to your other systems. For example, if a SaaS IoT platform does not provide long-term data storage, you will need to create a bridge that pulls data from the platform’s service and puts it into a database that you control in the cloud. Maintaining and monitoring this bridge is non-trivial which may lead to you wanting to consolidate everything into your existing cloud. For reasons like this, we typically recommend PaaS platforms at this stage.

If you already have connected products out in the market…

The connected or accelerating stages are all about maximizing the benefit of IoT, taking advantage of the valuable data you are likely getting, and aligning your costs to revenue. You should be focused on scaling up your system while you improve your connected customer relationships and build up new processes and skills. These are not insignificant tasks. It takes in-house expertise. Your team needs to understand your systems, be able to improve efficiencies and optimize costs. You’ve got to get data to the right place when you need it, and it has to drive reliable actions across all your infrastructure.

PaaS IoT platforms offer the most advantage at this stage. You have more control of your systems and are not locked into a specific software platform. You have the ability to customize and have tighter integration with your existing systems. This lets you adapt and evolve to meet the needs of your customers over time.

Which production architecture works for you?

Considering the needs of your production system likely go beyond the needs of your prototypes and minimum viable product (MVP), it is best to think about what additional features you will need to augment the capabilities of your selected IoT platform. The diagrams below show the difference between augmenting a SaaS platform versus a PaaS platform.

An IoT System Built Around SaaS Platform

An IoT System Built on a PaaS Platform

What else should be considered when choosing an IoT Platform?

When selecting an IoT platform, you are also choosing an ecosystem to join. This has ramifications that go beyond just the platform. Consider the following questions:

- What device types are already supported / how easy is it to support the devices I need?

- How close does the platform fit my use-case?

- How easy is it to get started and use?

- What skills do I need on my team to utilize the platform?

- Will my team get the support we need to succeed?

- Is the service reliable / highly available / trustworthy?

- What additional features and services will I have to develop?

- What systems do I need to integrate with? How easy is that?

- What will my ongoing costs be for the IoT platform as well as other systems I need to maintain.

- What happens if I want to change to a different IoT Platform?

- Am I building the skills and knowledge we need inside my organization to succeed in the future?

Jumpstarting your IoT Systems with Starter Components

Building a system based on a PaaS platform offers a lot of flexibility and control. But you are faced with configuring and deploying your own applications to get your system running. There are a lot of reasons why you don’t want to create things from scratch. You need a head start. You need to follow good patterns and industry best practices. So, what should you do?

We believe that starter components, a.k.a. solution templates, solution implementations, etc, offer a great jumpstart to standing up a robust system. The big cloud companies know this and offer templates for various use-cases. These can be used in any stage of the IoT Journey. For example, AWS has a Smart Product Solution solution implementation that features capabilities to connect devices, process and analyze telemetry data, etc within a scalable framework. A fundamentally great feature of this is that it is based on AWS Cloud Development Kit (CDK) which means it can be programmatically deployed in minutes. Microsoft Azure has similar solution examples that can also be deployed and tested relatively quickly.

Additionally, there are a lot of benefits from working with a solution provider that has experience with IoT systems and can offer good guidance and support. SpinDance recently collaborated with our partner TwistThink to build Auris Cloud, a set of customizable IoT components that capture our combined years of experience working on IoT systems. Auris components are customizable to meet the needs of many different types of use cases and are deployable on AWS. Things like security, performance, and scalability are baked into the system. Auris can be optimized for different performance and cost models, integrated with other systems, and deployed as an application that you control. We believe this approach offers a great trade-off between fully custom and off-the-shelf solutions.

Summary

At SpinDance, we don’t recommend you try to build an IoT system from scratch. There are great solutions available from both SaaS and PaaS providers. They offer massive benefits in enabling you to build secure and scalable IoT solutions. However, we recommend you consider your organization’s goals and the stage you are in before locking yourself into an IoT platform. Be sure to start with your customer needs and build backward. Prototype and get things right before scaling. A SaaS IoT platform can be great for building proof of concepts or prototyping but may not work for you long term. For maximum customization, flexibility, and tighter integration with your other cloud applications we recommend a PaaS IoT platform. And for the lowest risks and maximum benefits, we recommend using pre-built components that can be customized to your needs.

How often have you wondered if you have turned off the oven in your kitchen or locked the main door of your house? IoT-powered devices are here to make lives easier and remind you of the necessary actions. Mobile IoT-based applications deliver mobility to control devices and gadgets remotely, regardless of one’s location. This blog post is focused to offer a better understanding of how IoT mobile app developments are becoming useful and how businesses can benefit from this trend.

Internet of Things (IoT), by now, does not need any introduction. However, in brief, IoT is a network of physical devices that are implanted with sensors, software and other technologies to connect and exchange data with other devices and systems over the internet. IoT has become an integral part of every aspect of our lives. From common household products to sophisticated industrial instruments, IoT connects numerous devices to simplify operations. Experts predict that by 2025, there will be more than 22 billion connected IoT devices worldwide. This digit is sure to take over the world by storm!

What makes mobile IoT the most popular trend?

Smartphones are used by billions of people around the world, and the number is growing every day. As a result of their ease of development, mobile apps make sense as the main channel for accessing IoT. It’s due to the reality of networked appliances that are easily accessed through mobile apps from any location, that improves people’s lives. Mobile is also significantly a more versatile platform for data transmission. IoT devices can be efficiently managed and monitored using a single application on a device. Mobile apps play a significant role in the rise of IoT.

What's the connection between IoT devices and mobile apps?

An IoT device and a mobile phone communicate through a mobile app. The mobile app serves as the primary interface for controlling smart devices. Also, to increase the effectiveness of IoT, mobile IoT apps augment and enhance their utilization.

For instance, your phone can notify your coffee machine that you are approaching, allowing it to begin brewing coffee prior to your arrival. However, you may wonder that such IoT devices can be controlled from a desktop computer as well. Then, why should you have a mobile app? Here are two major reasons you should know:

- Mobile phones are better suited for accessing information from any location.

- Smartphones are jam-packed with sensors of all kinds. Wi-Fi, Bluetooth, and other wireless technologies are among the communication possibilities available to them.

Mobile phones not only transmit geolocation information to your devices with the help of mobile IoT apps but are the most convenient devices for managing IoT technologies because of their characteristics.

What are the benefits of IoT-based mobile apps?

IoT-enabled services provide access, increase efficiency and drive greater personalization. Most IoT use cases are classified through the following three categories:

- Enabling access: Mobile-enabled IoT devices can ensure service delivery in remote areas.

- Improving efficiency: By real-time tracking of machinery, equipment, and field workers, businesses can gain insights, visibility and control through IoT, resulting in reduced waste, production boost, improved safety and extended life of assets.

- Personalization: Businesses can better understand and profile their customers using customer analytics, allowing them to give more tailored services on an individual level, altering the customer experience.

What are some examples of mobile IoT development?

IoT is changing everyday aspects to enrich our lives by generating information to improve our convenience. It is bringing more and more things into the digital fold.

The capacity of IoT to supply sensor data and enable device-to-device communication is driving a wide range of applications. Let’s find out some of the most popular use cases and what they accomplish:

- Improving equipment and product quality monitoring to aid manufacturing efficiencies

With the help of IoT assistance, manufacturing machines can be monitored and examined on a continual basis to ensure that they are operating within acceptable tolerances. Moreover, quality faults can also be identified and addressed by monitoring products in real-time.

- Enhancing physical asset tracking

Businesses can easily track assets to find out where they are. They can utilize ring-fencing to protect high-value assets from being stolen or lost.

- Tracking human health and environmental factors through wearables

IoT wearables assist customers in better understanding their own health and allow clinicians to remotely monitor patients. This technology also enables organizations to monitor their employees' health and safety, which is particularly useful for those who work in hazardous situations.

- Embracing new possibilities

One example is the application of IoT in connected logistics for fleet management to improve efficiency and safety. Companies can utilize IoT fleet monitoring to increase efficiency by directing trucks in real-time.

- Innovating business processes

This is demonstrated by the usage of IoT devices for linked assets to monitor the health of remote machines and initiate service calls for preventive maintenance. Remote machine monitoring is also enabling new product-as-a-service business models, in which customers pay to use rather than acquire a product.

The final say

Mobile apps are at the forefront of IoT as we always have our smartphones handy. Smartphones also include a lot of sensors, which makes it easy to handle smart devices and gadgets. Undoubtedly, the market for IoT smartphone apps has a promising future through mobility. In the following years, IoT investments, as well as the number of connected devices and mobile applications, are predicted to skyrocket.

Internet of Things (IoT) today has brought a significant change in our day-to-day lives. And, with connectivity improving in the last few years it has become more widespread with the passing time. This technology has gained a lot of traction with the help of growing mobile technology. It is expected to witness a surge in the number of IoT applications that are expected in the coming years.

So, it wouldn’t come as no surprise that companies are now starting to consider the integration of this nifty technology with iOS app development. This is because of the benefits such as ease of data collection, employee mobility, process automation, etc.

The integration of IoT into iPhone app development is one of the hottest technologies. It is making the rounds these days. Interestingly, this helps create numerous business opportunities for many enterprises across various sectors as more and more people find their way into the connected world of devices with data.

Before we move on to discussing how one can pick the right IoT development provider, allow us to also quickly list some of the main challenges you are likely to face during this process.

The development of IoT-driven iOS apps is also subject to a plethora of challenges and concerns as is any other digital product. Nonetheless, in the specific context of IoT apps, some of the key issues that are likely to emerge during the development process are connectivity, compatibility, privacy, and security. We mention these challenges to help you ensure that these challenges are properly addressed during the development process.

Now, some tips to help you find the right service provider for developing iPhone apps fortified with IoT.

1. Before you set off to find a development partner for your IoT-fortified iOS development project, it is highly advisable that you first take the time to understand precisely why you want to develop such an app. Take the time to elucidate the goal of developing such an app, what you expect to achieve with it, who is your target audience, etc. All these factors will, then, help you understand what your app should look like, the features it must have, the challenges you will face, and the kind of skills and experience you will need to help you get through this process with a robust product on the other end.

2. The next factor you must keep in mind while looking for a development partner is that the company you choose must be able to help you build a top-quality IoT-driven iOS app and that too without burning a hole in your pockets. What that means is to find a service provider who can deliver the required product without needing massive investments.

3. Now that IoT has firmly established itself as a force to be reckoned with, plenty of development service providers are looking to cash in on the popularity of this new technology. However, that does not necessarily mean they have the skill or experience one needs to develop high-quality iPhone apps. This is why experts recommend opting for a reputed company, even if engaging their services is comparatively more expensive. This will help ensure the timely development of a robust app.

It is clear as day to see that IoT brings a whole lot of value to the table, more so when it comes to iOS apps and their development. We understand trying to embrace new technology in your business and apps can be an intimidating endeavor, but hopefully, the above discussion can help allay some of the concerns you may have had about the process. For the rest, it is advisable to find an expert development company that has the relevant skills for developing iPhone apps for your business and the industry in which you operate. Once you find a trusted development partner, the rest of the process will be rather simple to navigate through.

Today the world is obsessed with the IoT, as if this is a new concept. We've been building the IoT for decades, but it was only recently some marketing "genius" came up with the new buzz-acronym.

Before there was an IoT, before there was an Internet, many of us were busy networking. For the Internet itself was a (brilliant) extension of what was already going on in the industry.

My first experience with networking was in 1971 at the University of Maryland. The school had a new computer, a $10 million Univac 1108 mainframe. This was a massive beast that occupied most of the first floor of a building. A dual-processor machine it was transistorized, though the control console did have some ICs. Rows of big tape drives mirrored the layman's idea of computers in those days. Many dishwasher-sized disk drives were placed around the floor and printers, card readers and other equipment were crammed into every corner. Two Fastrand drum memories, each consisting of a pair of six-foot long counterrotating drums, stored a whopping 90 MB each. Through a window you could watch the heads bounce around.

The machine was networked. It had a 300 baud modem with which it could contact computers at other universities. A primitive email system let users create mail which was queued till nightfall. Then, when demands on the machine were small, it would call the appropriate remote computer and forward mail. The system operated somewhat like today's "hot potato" packets, where the message might get delivered to the easiest machine available, which would then attempt further forwarding. It could take a week to get an email, but at least one saved the $0.08 stamp that the USPS charged.

The system was too slow to be useful. After college I lost my email account but didn't miss it at all.

By the late 70s many of us had our own computers. Mine was a home-made CP/M machine with a Z80 processor and a small TV set as a low-res monitor. Around this time Compuserve came along and I, like so many others, got an account with them. Among other features, users had email addresses. Pretty soon it was common to dial into their machines over a 300 baud modem and exchange email and files. Eventually Compuserve became so ubiquitous that millions were connected, and at my tools business during the 1980s it was common to provide support via this email. The CP/M machine gave way to a succession of PCs, Modems ramped up to 57 K baud.

My tools business expanded rapidly and soon we had a number of employees. Sneakernet was getting less efficient so we installed an Arcnet network using Windows 3.11. That morphed into Ethernet connections, though the cursing from networking problems multiplied about as fast as the data transfers. Windows was just terrible at maintaining reliable connectivity.

In 1992 Mike Lee, a friend from my Boys Night Out beer/politics/sailing/great friends group, which still meets weekly (though lately virtually) came by the office with his laptop. "You have GOT to see this" he intoned, and he showed me the world-wide web. There wasn't much to see as there were few sites. But the promise was shockingly clear. I was stunned.

The tools business had been doing well. Within a month we spent $100k on computers, modems and the like and had a new business: Softaid Internet Services. SIS was one of Maryland's first ISPs and grew quickly to several thousand customers. We had a T1 connection to MAE-EAST in the DC area which gave us a 1.5 Mb/s link… for $5000/month. Though a few customers had ISDN connections to us, most were dialup, and our modem shelf grew to over 100 units with many big fans keeping the things cool.

The computers all ran BSD Unix, which was my first intro to that OS.

I was only a few months back from a failed attempt to singlehand my sailboat across the Atlantic and had written a book-length account of that trip. I hastily created a web page of that book to learn about using the web. It is still online and has been read several million times in the intervening years. We put up a site for the tools business which eventually became our prime marketing arm.

The SIS customers were sometimes, well, "interesting." There was the one who claimed to be a computer expert, but who tried to use the mouse by waving it around over the desk. Many had no idea how to connect a modem. Others complained about our service because it dropped out when mom would pick up the phone to make a call over the modem's beeping. A lot of handholding and training was required.

The logs showed a shocking (to me at the time) amount of porn consumption. Over lunch an industry pundit explained how porn drove all media, from the earliest introduction of printing hundreds of years earlier.

The woman who ran the ISP was from India. She was delightful and had a wonderful marriage. She later told me it had been arranged; they met their wedding day. She came from a remote and poor village and had had no exposure to computers, or electricity, till emigrating to the USA.

Meanwhile many of our tools customers were building networking equipment. We worked closely with many of them and often had big routers, switches and the like onsite that our engineers were working on. We worked on a lot of what we'd now call IoT gear: sensors et al connected to the net via a profusion of interfaces.

I sold both the tools and Internet businesses in 1997, but by then the web and Internet were old stories.

Today, like so many of us, I have a fast (250 Mb/s) and cheap connection into the house with four wireless links and multiple computers chattering to each other. Where in 1992 the web was incredibly novel and truly lacking in useful functionality, now I can't imagine being deprived of it. Remember travel agents? Ordering things over the phone (a phone that had a physical wire connecting it to Ma Bell)? Using 15 volumes of an encyclopedia? Physically mailing stuff to each other?

As one gets older the years spin by like microseconds, but it is amazing to stop and consider just how much this world has changed. My great grandfather lived on a farm in a world that changed slowly; he finally got electricity in his last year of life. His daughter didn't have access to a telephone till later in life, and my dad designed spacecraft on vellum and starched linen using a slide rule. My son once saw a typewriter and asked me what it was; I mumbled that it was a predecessor of Microsoft Word.

That he understood. I didn't have the heart to try and explain carbon paper.

Originally posted HERE.

Only for specific jobs

Just a few decades ago, headsets were meant for use only with specific job functions – primarily B2B. They were used as simply extensions of communication devices, reserved for astronauts, mission control engineers, air traffic controllers, call center agents, fire fighters, etc. who all had mission critical communication to convey while their hands had to deal with something more important than holding a communication device. In the B2C consumers space you rarely saw anyone wearing headsets in public. The only devices you saw attached to one’s ears were hearing aids.

Tale of two cities: Telephony and music

Most headsets were used for communication purposes, which also referred to as ‘Telephony’ mode. As with most communications, this requires bi-directional audio. Except for serious audiophiles and audio professionals, headsets were not used for music consumption. Any type of half-duplex audio consumption was referred to as ‘Music' mode.

Deskphones and speakerphones

Within the enterprise, a deskphone was the primary communication device for a long time. Speakerphones were becoming a common staple in meeting rooms, facilitating active collaboration amongst geographically distributed team members. So, there were ‘handsets’ but no ‘headsets’ quite yet.

Mobile revolution: Communication and consumption

As the Internet and the browser were taking shape in the early ’90s, deskphones were getting untethered in the form of big and bulky cellular phones. At around the same time, a Body Area Network (BAN) wireless technology called Bluetooth was invented. Its original purpose was simply to replace the cords used for connecting a keyboard and mouse to the personal computer.

As cellular phones were slimming down and becoming more mainstream, scientists figured out how to use Bluetooth radio for short-range full-duplex audio communications as well. Fueled by rapid cell-phone proliferation, along with the need for convenient hands-free communication by enterprise executives and professionals (for whom hands-free communication while being mobile was important), monaural Bluetooth headsets started becoming a loyal companion to cell phones.

While headsets were used with various telephony devices for communications, portable analog music (Sony Walkman, anybody?) started giving way to portable digital music. Cue the iPod era. The portable music players primarily used simple wired speakers on a rope. These early ‘earbuds’ didn’t even have a microphone in them because they were meant solely for audio consumption – not for audio capture.

The app economy, softphones and SaaS

Mobile revolution transformed simple communication devices into information exchange devices and then more recently, into mini super computers that have applications to take care of functions served by numerous individual devices like a telephony device, camera, calculator, music player, etc. As narrowband networks gave way to broadband networks for both the wired and wireless worlds, ‘communication’ and ‘media consumption’ began to transform in a significant way as well.